Bridging AI & IoT: My Technical Projects

Exploring my AI-driven technical projects—CodeLimb and VisionMed—and how they push the boundaries of intelligent systems and automation.

Technology has the power to enhance lives, automate industries, and create solutions that adapt to real-world challenges. My work in AI, IoT, and embedded systems is centered around building intelligent automation solutions that bridge software and hardware seamlessly.

This blog post highlights two key projects that showcase the intersection of AI, real-time processing, and automation:

✅ CodeLimb – A bionic arm that enables intuitive movement using AI-driven control.

✅ VisionMed – An AI-powered quality control system that automates pharmaceutical inspection.

- 🚀 CodeLimb: AI-Powered Bionic Arm

- 🩺 VisionMed: AI-Driven Quality Control in Pharmaceuticals

- Why These Projects Matter

🚀 CodeLimb: AI-Powered Bionic Arm

Revolutionizing Assistive Technology with AI & IoT

CodeLimb is an AI-driven bionic arm that replicates natural hand movements, integrating machine learning, IoT connectivity, and real-time sensor feedback. Designed for individuals with limb loss, the system uses embedded microcontrollers and muscle signal detection to execute precise motions.

Key Features & Technologies:

🔹 Real-time motion tracking – Converts electrical signals into fluid hand movements.

🔹 Machine learning-based adaptability – AI continuously learns from user interactions.

🔹 IoT connectivity – Enables remote monitoring and calibration.

🔹 Low-latency embedded system – Ensures immediate response to muscle signals.

| Component | Technology Used |

|---|---|

| Microcontroller | STM32 for real-time motion processing |

| Machine Learning | TensorFlow & PyTorch for gesture recognition |

| Sensors | EMG (Electromyography) for muscle signal detection |

| Actuators | Servo motors for precision control |

| IoT Integration | MQTT & cloud-based monitoring |

Impact of CodeLimb

✅ Enhances mobility and functionality for users with limb loss.

✅ Bridges AI-driven intelligence with physical hardware.

✅ Opens possibilities for next-gen prosthetics and smart assistive devices.

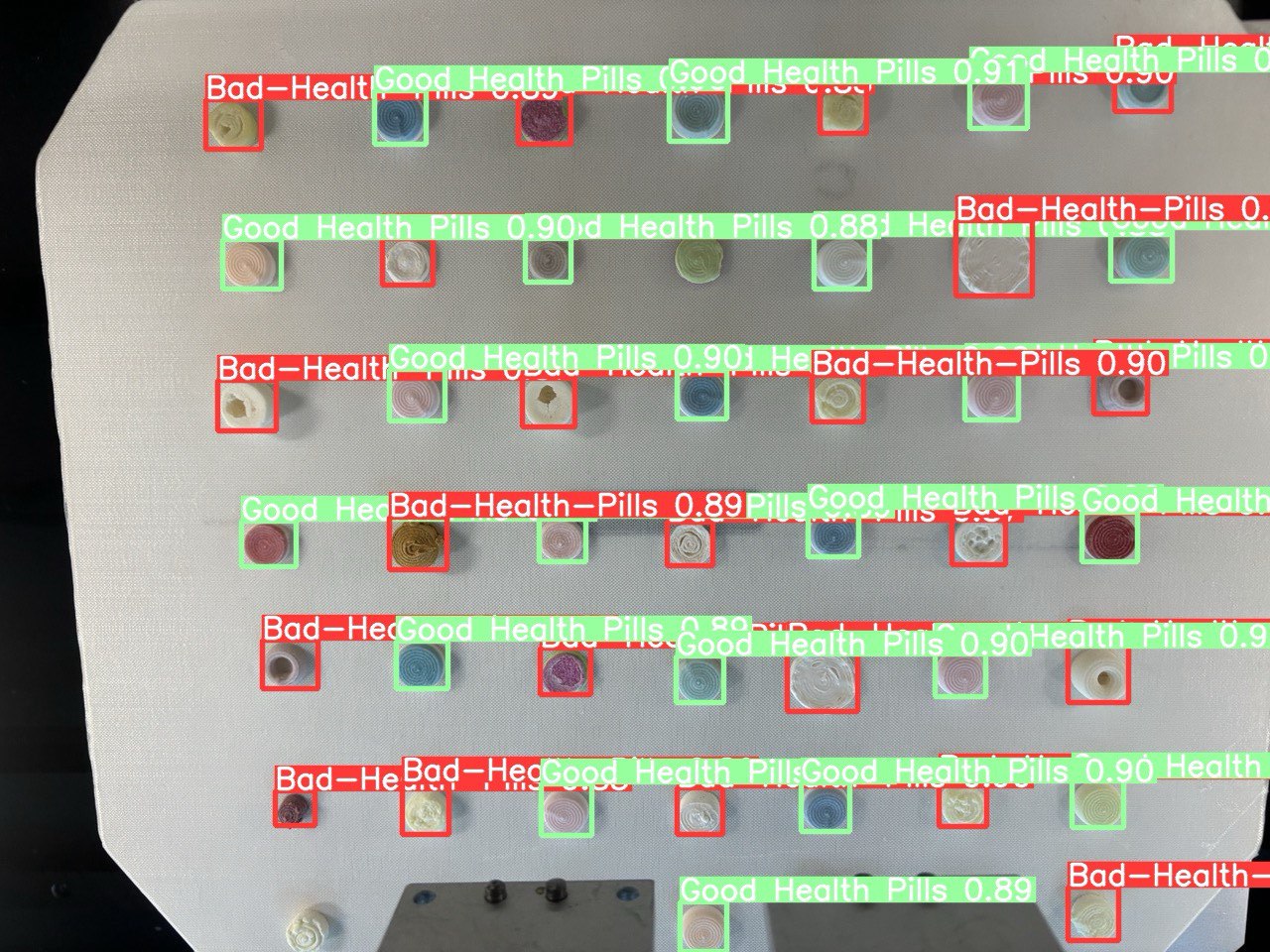

🩺 VisionMed: AI-Driven Quality Control in Pharmaceuticals

Optimizing Medical Manufacturing with Computer Vision

VisionMed is a computer vision system designed to automate tablet inspection and quality control in pharmaceutical manufacturing. Using AI-powered image recognition and defect detection, VisionMed ensures 100% accuracy in medical tablet classification, reducing human error and production inefficiencies.

Key Features & Technologies:

🔹 Deep learning-based image processing – Identifies defective tablets in real time.

🔹 Automated defect detection – Flags inconsistencies in color, shape, and size.

🔹 Edge AI optimization – Runs models efficiently for high-speed processing.

🔹 Seamless industrial integration – API connectivity for automation systems.

| Component | Technology Used |

|---|---|

| Computer Vision | OpenCV for image preprocessing |

| Deep Learning Model | CNNs for defect detection & classification |

| AI Frameworks | TensorFlow & PyTorch for training models |

| Automation | Edge AI deployment for real-time analysis |

| Industrial Integration | API-based connectivity for manufacturing |

Impact of VisionMed

✅ Eliminates human error in pharmaceutical inspection.

✅ Increases efficiency & speed in quality control.

✅ Enhances patient safety by ensuring high manufacturing standards.

Why These Projects Matter

Both CodeLimb and VisionMed represent my commitment to building AI-driven solutions that enhance human life and industrial efficiency. They showcase how AI, IoT, and embedded systems can create intelligent, real-world applications in:

✅ Assistive Technology – Enhancing mobility and independence.

✅ Automation & Quality Control – Improving efficiency in manufacturing.

✅ AI-Embedded Systems – Bridging hardware & software for next-gen solutions.

🚀 Let’s build the future of AI and automation together.