VisionMed

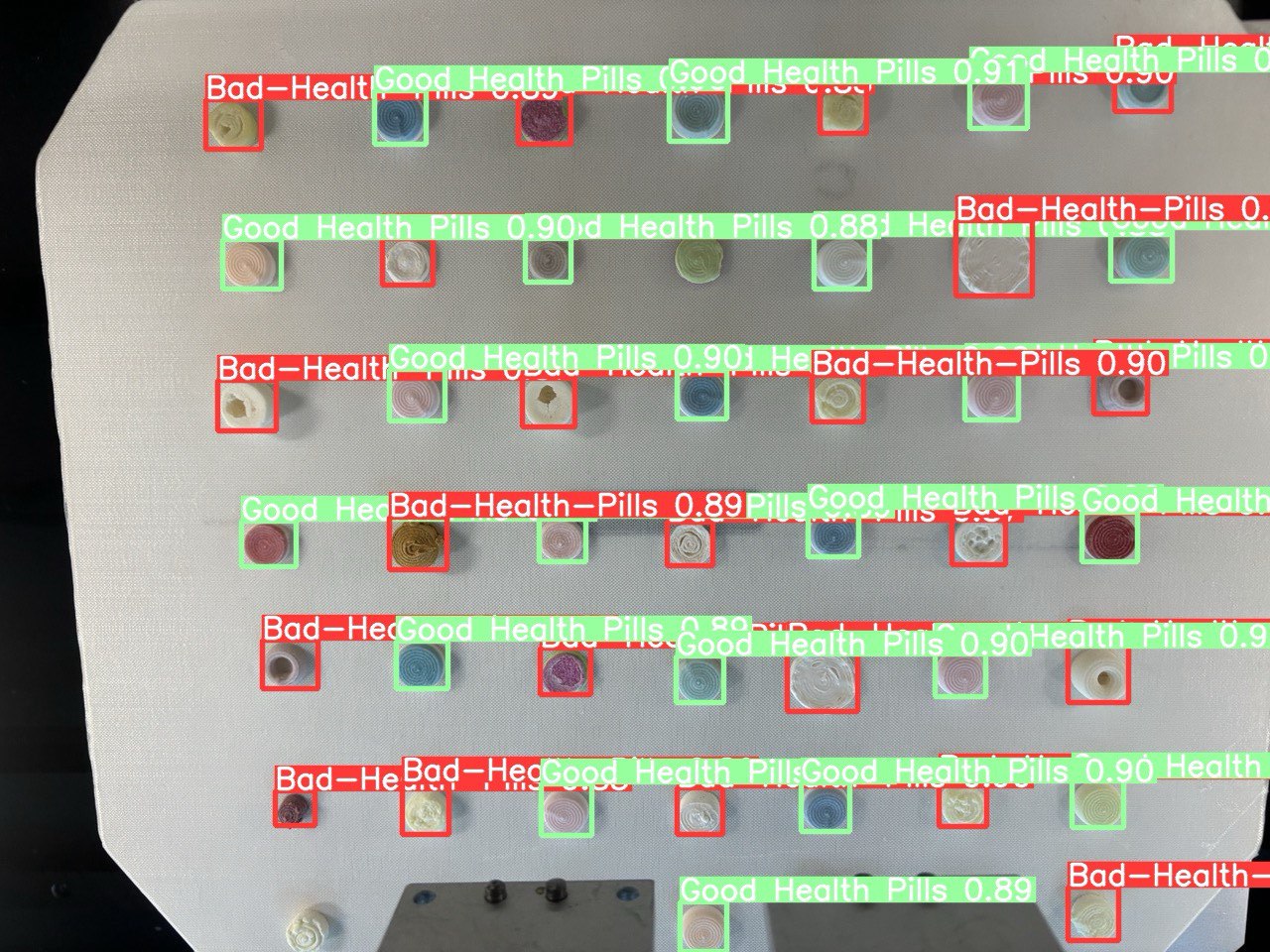

I worked on VisionMed, an AI-driven tablet identification and quality control system for pharmaceutical manufacturing. My contributions included developing image processing, object detection, and classification algorithms to ensure precise and automated tablet verification.

VisionMed: AI-Powered Pharmaceutical Quality Control

VisionMed is an advanced computer vision system designed to automate and enhance pharmaceutical quality control through real-time defect detection. By leveraging deep learning models, AI-driven automation, and edge computing, the system ensures precise identification of defective pharmaceutical tablets, improving both efficiency and accuracy in the manufacturing process.

The core of VisionMed is its convolutional neural network (CNN) models, trained on vast pharmaceutical datasets to identify defects, shape inconsistencies, discoloration, and imprint errors in real time. Built using TensorFlow and OpenCV, the model achieves high accuracy in classifying tablets, reducing manual inspection workload by over 50% and improving defect detection rates.

To optimize industrial implementation, VisionMed integrates Edge AI processing, allowing real-time analysis directly on embedded systems without relying on cloud computing. This reduces latency, enhances data security, and ensures scalability for large-scale pharmaceutical production lines. The system is also capable of automated sorting and rejection mechanisms, allowing immediate action when defective products are detected.

Future advancements will focus on expanding AI training datasets, improving adaptive learning for new tablet formulations, and optimizing model efficiency for real-time deployment in large-scale production environments. VisionMed is a transformative step in AI-driven quality control, ensuring safer, more reliable pharmaceutical manufacturing worldwide.